Repairing the Table of a 850 carat Imperial Topaz

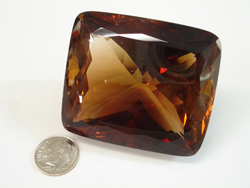

A gem dealer sent me this large Topaz which had been damaged on the table. It could not be sold in this condition and needed to be reparied.

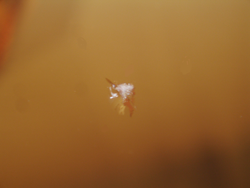

Something had struck the table of the Topaz which created a white spot on the surface of the stone where the material had been 'crushed'. This causes tiny fractures which extend down into the stone.

Repairing such a large table is extremely difficult. This project would prove to be quite a challenge for me.

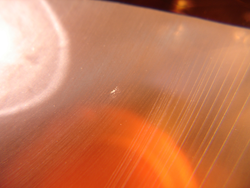

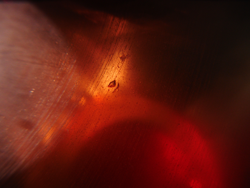

To do this project I needed to order a fresh new and sharp cutting lap to take down the table to get 'under' all of the tiny fractures.

Below, you will see photos and a description of the cutting process.